In today's fast-paced world, general manufacturing, retail, pharmaceuticals, food and drink manufacturing, and facilities management require efficient and reliable material handling systems and equipment to streamline operations and boost productivity. These systems offer multiple advantages, including increased efficiency, reduced labour costs, and improves health and safety in the workplace.

Discover the 7 benefits of why investing in material handling solutions can improve profitability and productivity:

1. Supports preventing injuries to workers

Selecting the right equipment that can lift, move, and store heavy materials in bulk will help reduce employee injuries, such as damage to hand ligaments and stress, when using automated materials handling equipment and systems, including conveyor belts and powered forklifts. Opting for these solutions eliminates workers needing to manually move materials that exceed their physical limitations and therefore increases safety.

2. Enhances efficiency

Materials handling equipment can increase workplace efficiency and productivity by improving the organisation's process of organising products and tasks. For example, focusing on bulk rather than single loads will reduce the likelihood of misplaced items in warehouses. This will minimise downtime costs and speed up production by reducing the number of back-and-forth trips.

3. Reduces the risk of product damage

When materials or products are moved manually across a site floor or transported, this increases the risk of product damage if not handled carefully. To avoid scenarios where workers can accidentally drop products on the floor resulting in breakage, manual handling equipment, including forklifts, are designed with a built-in counterbalance to stop them from tipping over when transporting heavy materials. They can provide the necessary protection needed to avoid costly damages.

4. Improves storage capacity

Appropriately organising storage for your warehouse can effectively maximise the available space, making it easier for staff to access products and equipment.

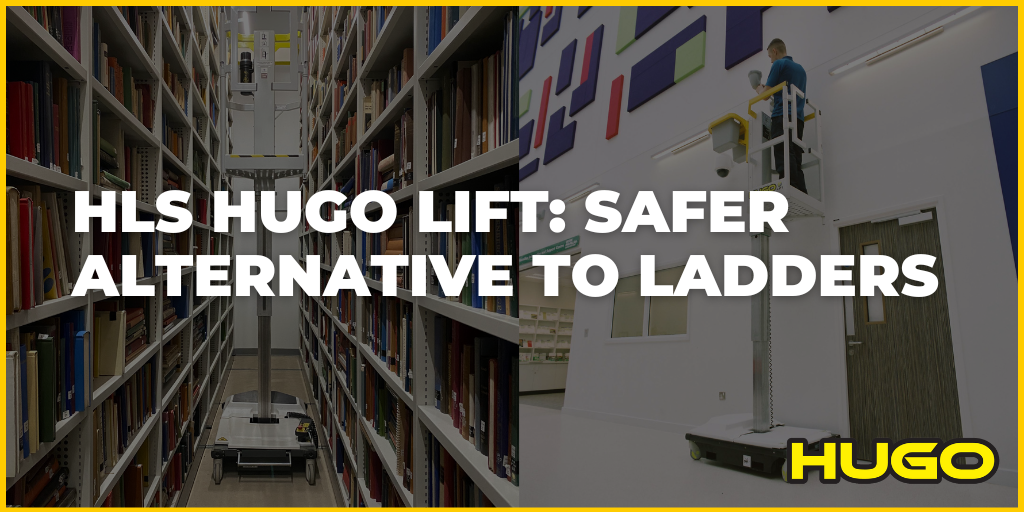

Businesses can save costs by optimising available workspace for workers, eliminating the need to search for additional inventory storage. This approach can also prevent accidents such as falls from heights by positioning materials in a place that does not obstruct other equipment such as mobile elevating work platforms.

5. Improves the quality of customer service

Using material handling equipment can speed up production and delivery times, leading to shorter shipping and delivery periods. This will guarantee that you retain your current customer base and attract new business through positive customer referrals.

6. Cost-effective

Expenses associated with material handling equipment may seem substantial on first observation, but it can save a significant amount of money in the long term. This equipment makes the production of materials more efficient without exceeding the budget or requiring additional workforce.

Many businesses are facing challenges in hiring skilled employees due to economic difficulties and inflation. However, they can overcome this by implementing materials handling techniques that enable them to accomplish tasks like sorting, shipping, and handling items with fewer people. This not only increases productivity but also speeds up the process.

7. Improve the morale of operators

Workers can feel more confident that they can perform their tasks safer and feel more motivated to accomplish what needs prioritising in a short time without worrying about encountering accidents that could cost the business. Overall, this increases productivity and creates a positive workplace culture where workers will feel more relaxed if there is an organised process for storing products, as this increases misplacement.

If you are seeking advice on enhancing your operational efficiency through material handling solutions, we can assist you. Our extensive range of equipment, including pallet trucks and forklift trucks, can cater to your various lifting requirements.

You can contact the team by calling 0113 524 1018 or emailing sales@hls.co