www.freeimage.com by Marco Michelini

Positive safety culture… It sure sounds like one of those new wave phrases that often contain more idealism and naivety than common sense. Safety culture, however, has very little to do with any current quixotic movements and has a growing presence in the public eye. So, what is safety culture, why is it important and how can it change your company? To learn everything you need to know and whether you need to acquire one, keep on reading.

While most companies consider safety culture as the inclination of their employees to follow and comply with established safety regulations, safety culture is much more than just putting together a policy for your staff to follow. It’s an outcome of genuine concern and good leadership; it practices good worker involvement and exhibits well-developed communication between management and employees; it’s the foundation upon which a company is built and the context within which people judge the appropriateness of their behaviour.

'Ultimately a positive safety culture is one where everybody in the organisation, from top to bottom, has a daily focus on safety and risk reduction in the jobs that they do, within the environments they work in,' says Richard Barnes, Managing Director of Culturetracker.com Limited.

Safety culture is about embracing the interactions between the working environment, equipment, systems and procedures, and the people in the organisation. It’s a symbiotic process, each of these depending on each other in order to function accordingly. For a good safety culture to thrive you will need to have an in-depth understanding about where safety problems lie within your business, as well as embrace your responsibility as a leader to create customs, values and norms and monitor if they are adhered to.

'In this day and age litigation in relation to safety failings is becoming more common, so even though directors have always had considerable responsibilities for health and safety duties, the extent to which they perhaps have paid attention to them has not been as great as it tends to be now,' Richard explains. The level of sentencing that the new Sentencing Guidelines are introducing will significantly raise the financial risk of a health and safety breach. The Corporate Homicide Act failed to present itself as a serious threat when it came to the issue of corporate liability and people going to jail. 'I think for many companies the real risk of major financial impact on the business plus the ability of the HSE to charge for their time, has now made that become more of a financial reality in people’s minds at directors’ levels.'

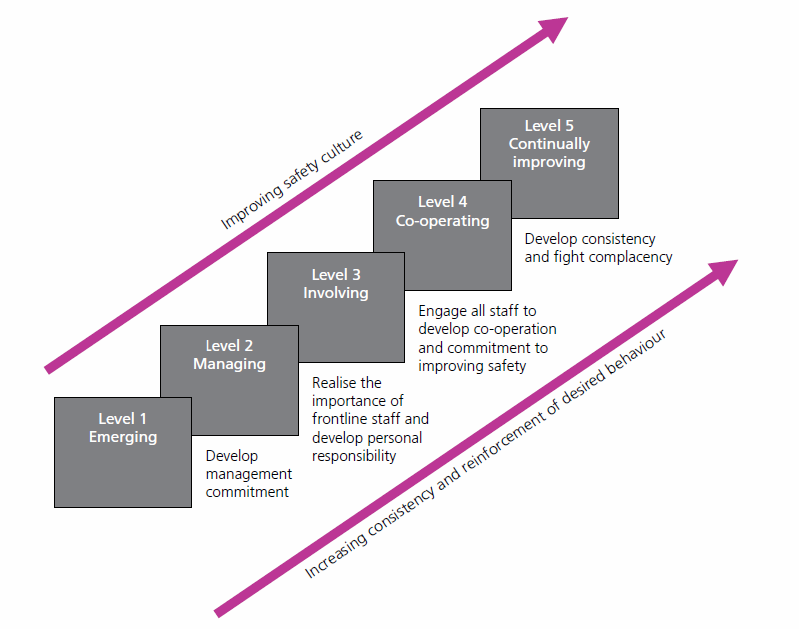

There are five main groups of organisational cultures in which your company can fall into, depending on their progress on the safety ladder.

- Pathological cultures – companies that own this type of culture believe that individuals are the cause of accidents and they are heavily based on blame. They implement only clear regulatory requirements and do so only in order to avoid prosecution. As individuals are generally held accountable for incidents in pathological cultures health and safety management systems are unlikely to be adopted.

- Reactive cultures – they understand the importance of health and safety, but believe that most problems lie within the lower level of the workforce. The companies who possess this type of culture tend to have very basic organisational and individual health and safety management skills.

- Calculative cultures – these companies who possess this type of culture value the systems for managing health and safety performance and use a large number of tools and training. However, their main focus is on the tools and analysis of metrics and often effectiveness is overseen.

- Proactive cultures – they consider health and safety as a core value and the leadership genuinely cares about the well-being of their employees. There is a high level of understanding of the role of management system failures as primary causes of accidents and there are performance targets in place. The focus of these companies is on continuous improvement and they use tools that simplify work processes and support line management as well as the workforce.

- Generative cultures – they realise the benefit of health and safety on their entire operating environment and health and safety is part of what they do on daily basis. [1]

The safety culture phrase dates back to the Chernobyl reactor disaster in 1986, the worst nuclear power plant accident in terms of casualties and cost in history. What came out of this incident was the realisation that having organisational safety structures is not sufficient enough to prevent a catastrophic accident, and the gap between policy and practice is absolutely vital in order for safety systems to work effectively. According to studies, 90% of accidents happen due to human factors.[1] However, when we talk about human factors we can't portray a simple black and white picture and attribute them only to employees’ characteristics, education, values and abilities. Human factors extend beyond that and include:

- Factors in the workplace – such as equipment, the procedures the job involves and the pace of work.

- Organisational factors – such as leadership style and the resources the organisation commits to health and safety.

- More wide-ranging influencing factors – such as the political context employees are working in and the influence of the media.

The organism of a functional safety culture.

Without a doubt, some of the biggest influences on safety culture include management commitment, employee involvement as well as competence, training, communication, compliance with procedures and organisational learning, amongst others. As you can see, there could be a number of underlying causes that can lead to an accident and attributing them entirely to human error is rather illiberal.

Strong vs weak safety culture

When we talk about a company’s safety culture, we need to take into consideration that every organisation has some sort of safety management procedures in place due to legal obligations and regulations. Thus, when discussing the topic of safety culture we need to examine the level to which it has been developed, rather then dwell on its existence.

Even though not the norm, a poor safety culture tends to exist in companies that have poor processes and procedures and is often a reflection of how a business is run in the first place. The environment of such companies encourages unsafe working practices and considers them acceptable in order to produce results. However, quite often this comes back as poor product quality and poor financial control. To find out more about how much a poor health and safety system could cost your company, read our blog 'The Hidden Costs of Safety Failures'.

What is the reason behind this tendency for poor safety? 'It is a sad fact that awful lot of people in middle management, particularly the ones that have to “get the job done”, often don’t see safety risks in the same light as perhaps they need to, therefore managers at the very senior levels tend to never get on with it and don’t necessarily make an intervention,' says Richard. 'The problem with safety is that it’s an invisible element. You can look at somebody’s university degree and see what they’ve got, you can assess their performance, but with safety you’re very much trying to measure something which doesn’t happen.' Safety culture is built on prevention and you can't see prevention. 'You can see an accident, but you can't see the prevention of an accident,' Richard concludes.

If you’re encountering routine procedural violations, failure to comply with the company’s own safety management systems and the management decisions consistently put production or costs before safety, these are symptomatic of a poor safety culture. Other factors can include lack of leadership in an environment where management expectations get lost or mistranslated and where hints are dropped that it’s ok to make short cuts and risky behaviour is encouraged in order to meet production deadlines.

On the other hand, paying attention to your safety can have a number of benefits. It can lead to good business practice in general, such as organisational leadership, communications and effectiveness of procedures. It can also provide you with a competitive advantage against other companies in the market place.[2]

'That is something which in construction in particular has become a big selling point for organisations,' explains Richard. 'In recent years major road building projects like the Crossrail Tunnel and the Olympics Stadium has gone to organisations who have a very good safety track record and they are able to promote that. Their safety track record is part of the offering they make to clients and is associated with a premium value on the bids that they make. So, I think that also influences leadership attitudes.'

To find out everything you need to know about the benefits of having a positive safety culture and where to start from when creating one

References:

[1] http://www.system-concepts.com/articles/health-and-safety-articles/2013/develop-a-lasting-health-and-safety-culture.html

[2] http://www.hsl.gov.uk/resources/health-safety-insights/safety-culture-faster-higher-stronger-%E2%80%93-safer

Additional Reading:

Successful health and safety management, HSG 65

Reducing error and influencing behaviour, HSG48

ACSNI Study Group on Human Factors. Third report: Organising for safety. Advisory

Committee on the Safety of Nuclear Installations (1993) reprinted 1998, ISBN 0717608654

Health & Safety Climate Survey Tool, HSE Books, ISBN 071761462X HSE Books.