Download the HLS MEWP Pre-use Inspection Checklist

If you want to establish a work at height inspection plan that combines daily visual and functional checks by the operators, regular inspections and servicing schedules completed by competent people (usually CAP Certified engineers) - this checklist will help.

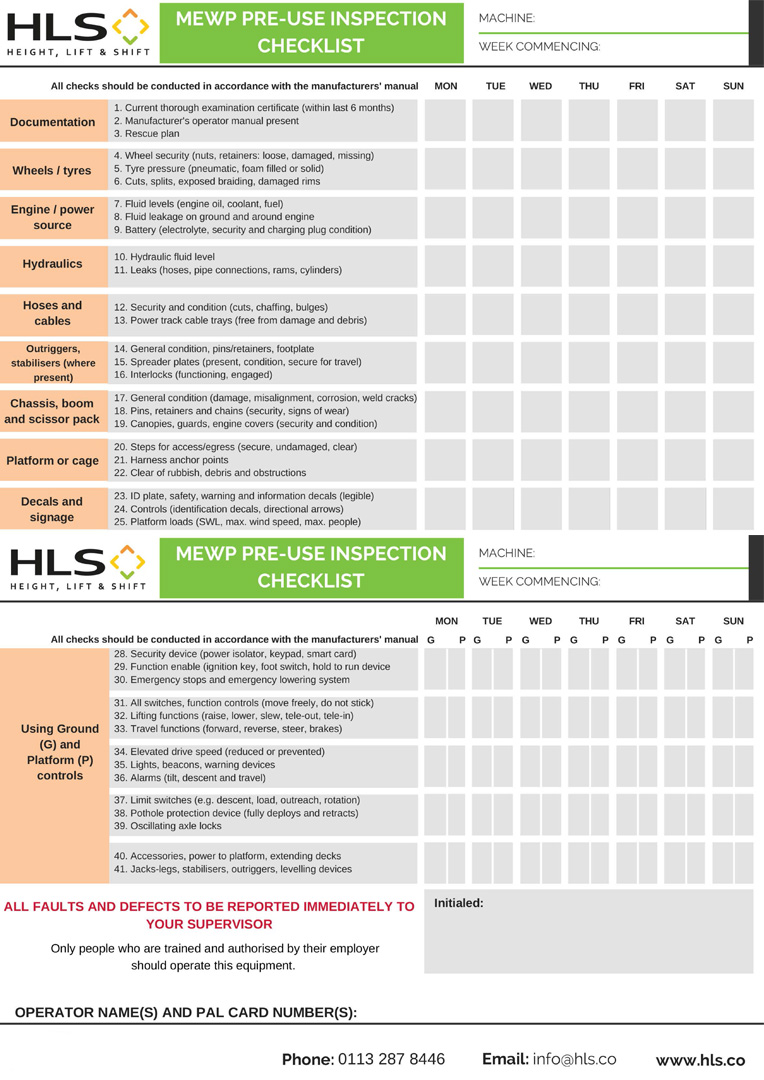

This handy checklist covers everything you should check before using a MEWP, it covers:

- Documentation

- Wheels/Tyres

- Power

- Platform check

- Decals and signage

- Using Ground and Platform controls

Just fill in the short form and your download will be available.

Fill In The Form Below To Download Your Free Checklist

Download the HLS MEWP Pre-Use Inspection Checklist

If you want to establish a comprehensive work at height inspection plan that combines daily operator checks, regular inspections, and servicing schedules by competent personnel (usually CAP-certified engineers), our MEWP Pre-Use Inspection Checklist is the perfect resource.

This checklist ensures that Mobile Elevating Work Platforms (MEWPs) are safe, fully functional, and compliant with current regulations, helping reduce risks to operators and your business. Simply fill in the short form to download your free copy instantly.

Understanding MEWPs and Their Risks

Mobile Elevating Work Platforms are essential tools for working safely at height, but they carry inherent risks if not properly maintained. According to the Health and Safety Executive (HSE), daily pre-use inspections are critical for identifying defects and deterioration before they become hazards. Many accidents occur due to overlooked issues like hydraulic leaks, worn tyres, or faulty safety controls.

Even small faults can result in serious injury or damage, making a structured inspection plan a legal and operational necessity.

Legal and Regulatory Requirements

Pre-use inspections are not just best practice—they are a legal requirement. Under the Provision and Use of Work Equipment Regulations 1998 (PUWER), operators are responsible for ensuring that MEWPs are maintained in safe working order. Similarly, LOLER regulations require all MEWPs to undergo a thorough examination by a competent person at least every six months.

Regular inspections protect your workforce, reduce downtime, and ensure compliance during audits. Keeping accurate records of all checks provides legal protection should an incident occur.

Why Daily Pre-Use Inspections Matter

Daily inspections help confirm whether a MEWP is safe to operate. By identifying issues early, operators can prevent accidents, maintain efficiency, and avoid costly repairs. Recording the results of inspections creates a clear trail of compliance, ensuring that maintenance, repairs, and thorough examinations are up to date.

A consistent inspection routine also builds confidence among operators, reducing human error and reinforcing a culture of safety on site.

Key Areas to Check

As part of the pre-use inspection, operators should review the following critical areas:

- Documentation: Current thorough examination certificate, operator manual, and rescue plan.

- Wheels and tyres: Checking for wheel security, correct pressure, and any signs of damage.

- Engine and power source: Fluid levels, leaks, and battery condition.

- Hydraulics: Inspecting fluid levels, hoses, rams, and cylinders for leaks or damage.

- Hoses and cables: Checking security, condition, and ensuring cable trays are clear of debris.

- Outriggers and stabilisers: Verifying correct setup, pins, retainers, spreader plates, and interlocks are functioning properly.

- Chassis, boom, and scissor pack: Inspecting for damage, corrosion, misalignment, and ensuring pins, chains, guards, engine covers, and canopies are secure.

- Platform or cage: Steps for access/egress, harness anchor points, and ensuring the area is clear of debris.

- Decals and signage: Ensuring ID plates, safety warnings, and operational labels are legible and correct.

- Controls (ground and platform): Testing all functions including emergency stops, lifting, travel, and reporting any faults immediately.

All faults or defects must be reported immediately. Only trained and authorised personnel should operate the MEWP.

Easy-to-Use Template

Our checklist comes as a Monday-to-Sunday template, making it easy for operators to tick off daily inspections and maintain consistent records.

By following this checklist, your organisation can enhance safety, maintain compliance, and reduce risk when using MEWPs.