Leading Bicycle Manufacturer

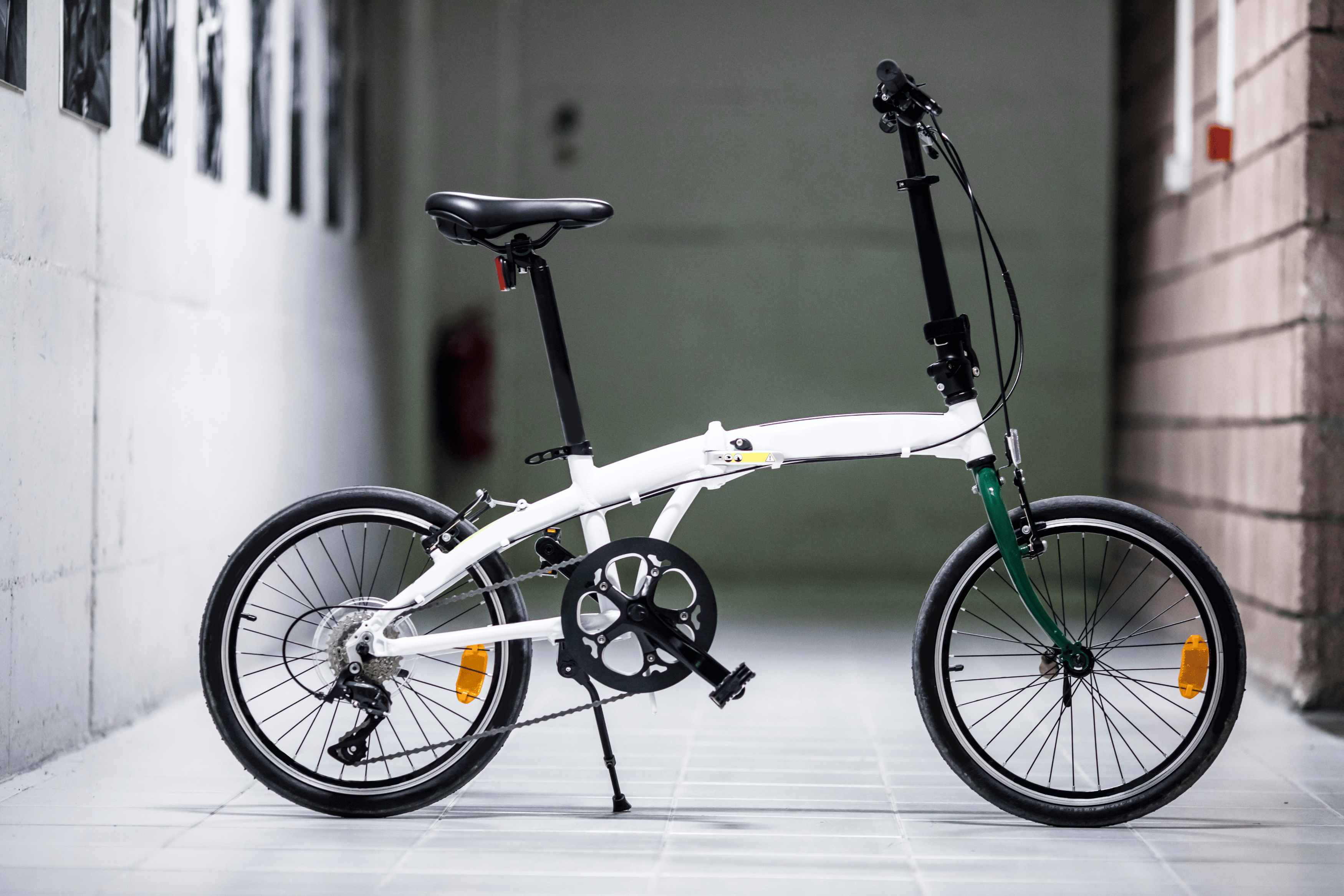

A renowned bicycle manufacturer, known for their innovative folding city bikes, wanted to safely improve its storage and handling processes within their expanding operations.

A renowned bicycle manufacturer, known for their innovative folding city bikes, wanted to safely improve its storage and handling processes within their expanding operations. With dedicated store areas and compact racking to house boxed folding bicycles. The company faced space restrictions and manual handling challenges as the inventory grew. To address these issues, they partnered with us (HLS) to find a safer, more efficient solution.

The Challenges

The manufacturer faced several key challenges within their facility:

- Limited Storage Space: Their current racking system for boxed folding bicycles was becoming inadequate, and they needed to maximise their storage capacity.

- Manual Handling Risks: Employees were responsible for manually lifting and storing bicycles, which increased the risk of strain and injury, as well as slowed down their overall productivity.

- Inefficient Operations: Concerns that the manual processes involved in handling bicycles could hinder their ability to meet growing operational demands quickly and safely.

Our Solution

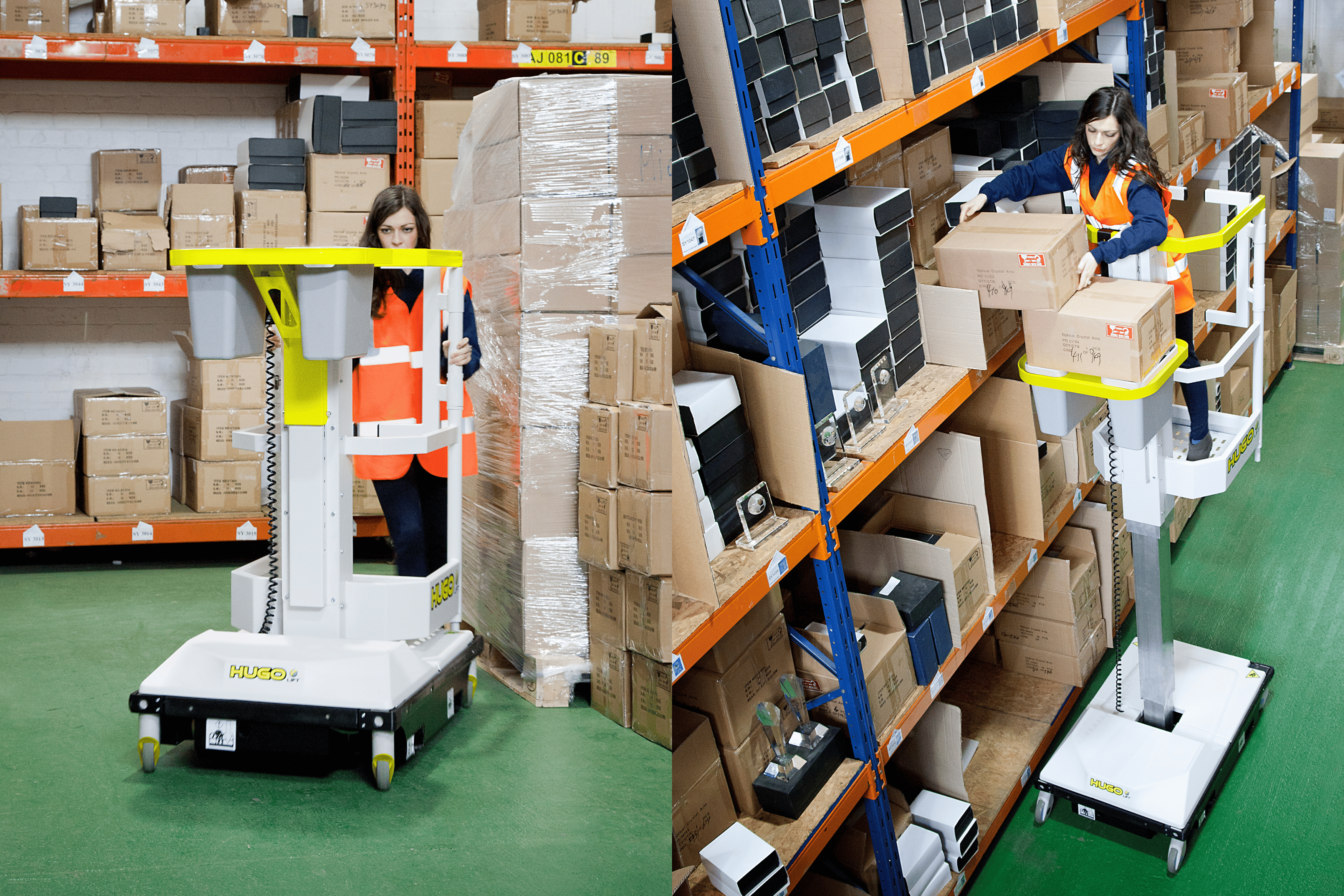

HLS introduced the Hugo Lift, a push-around vertical lift designed for indoor use, to solve the manufacturer’s challenges.

Key areas of the solution included:

- Maximised Storage Capacity: The Hugo Lift’s cargo shelf allowed staff to safely store bicycles on higher racks, making full use of the vertical space in the storage facility.

- Reduced Manual Handling: By utilising the Hugo Lift, employees no longer had to lift bicycles manually, reducing physical strain and enhancing workplace safety.

- Improved Workflow Efficiency: With the Hugo Lift, employees could transport boxed folding bicycles to the racking more quickly and efficiently, reducing handling time and improving productivity.

The Results

The company hired the Hugo Lift and noticed beneficial improvements:

- Increased storage capacity without requiring any major changes to their existing facilities.

- Reduced manual handling leading to fewer workplace injuries and a safer environment for employees.

- Improved efficiency in carrying out working at height tasks, allowing for quicker and more safer storage processes, which supported the company’s expanding production needs.

Sign up to our Newsletter

Explore our free online resource library featuring free downloads, blogs and exclusive videos.